step 2: TESTING ITS GLIDE

Whatever the board type, the glide quality must be impeccable.

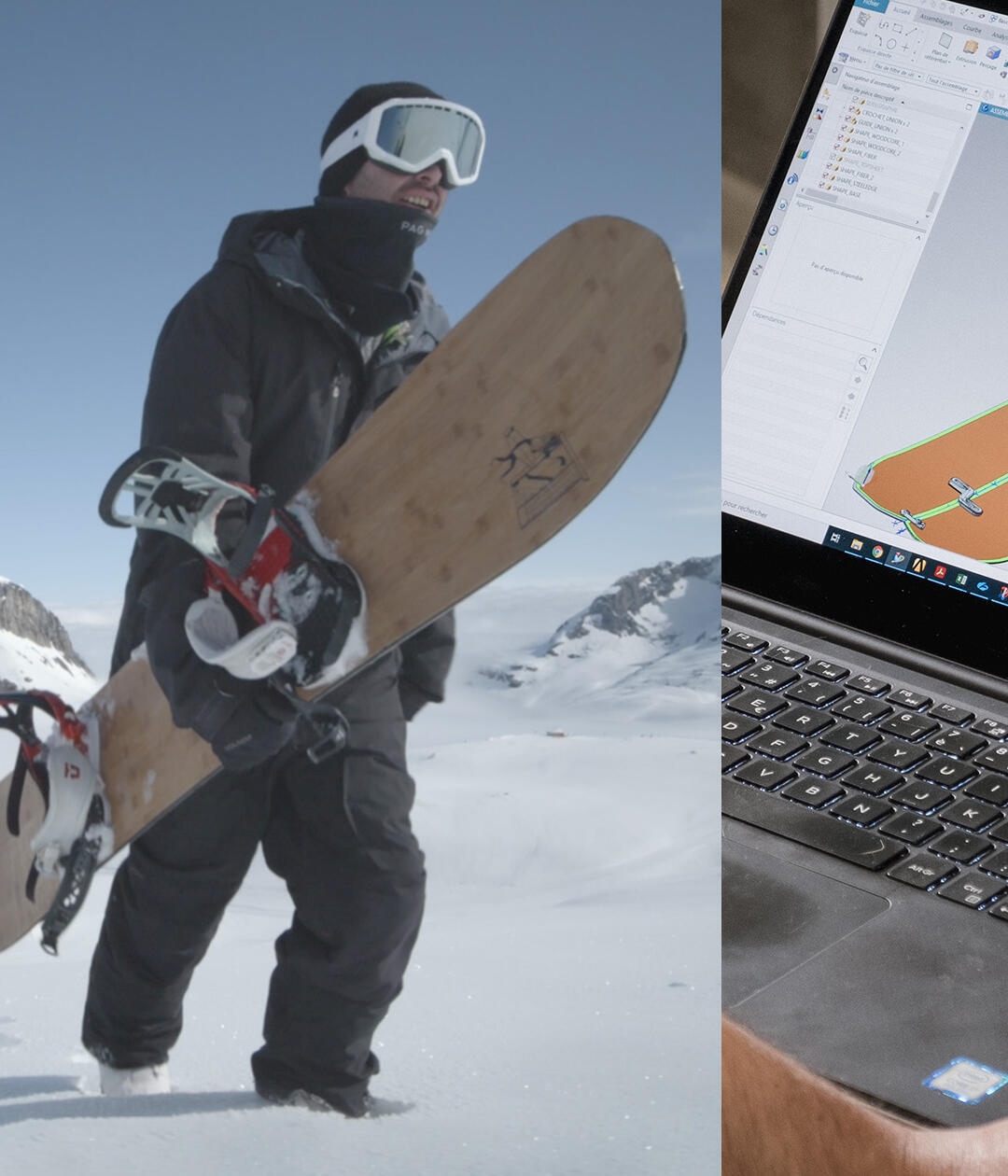

To test it, Franky will first glide on a slight slope with only the base in contact with the snow. At this stage, the idea is to try not to carve a turn but to test the base with simple pivots.

His debrief: "The board pivots and stops easily, the glide is easy and lets you manage the speed easily on the approach to rails or kicks"

Once the flat glide is validated, Franky can test it on curves. He starts with small turns then get longer little by little. The easier the glide, the easier it is to play with the board which is the most important feature of a freestyle board.

His debrief: "Very easy on small curves, less so on bigger ones. That's good as that’s what we’re looking for in a freestyle board, which above all requires management of small curves to adjust its speed before passing the modules. A short radius also lets you get quicker rotation on the kickers"